The overlay – nearly as hard as a diamond

To make HARO Laminate Floors particularly durable (keyword: micro scratch resistance), we finish the upper layer – the overlay – with corundum, the second hardest mineral after the diamond. But also the transparency of the overlay is of decisive importance: only by this the authentic look of the wood reproductions can be ensured. By the way: HARO has its own resin coating and creates its own overlays – of course with continuous quality controls in the production process for the necessary durability, scratch resistance and strength.

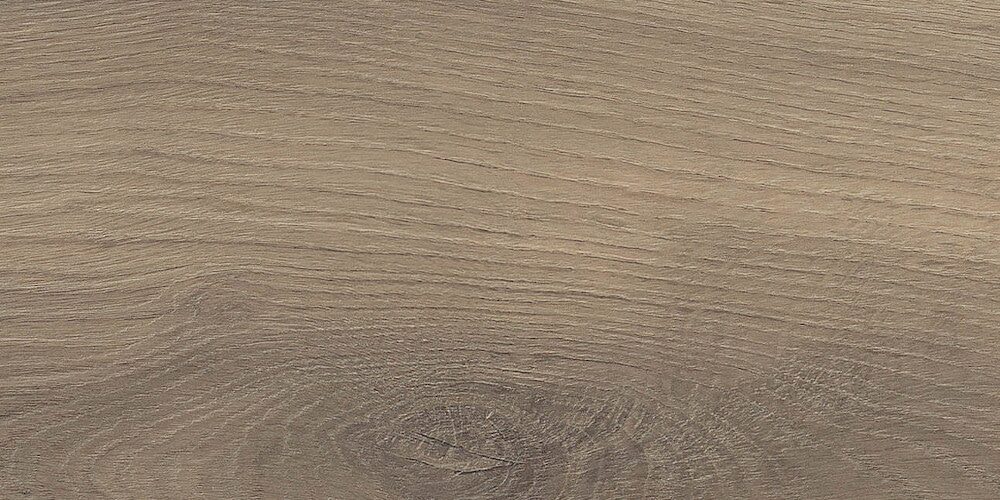

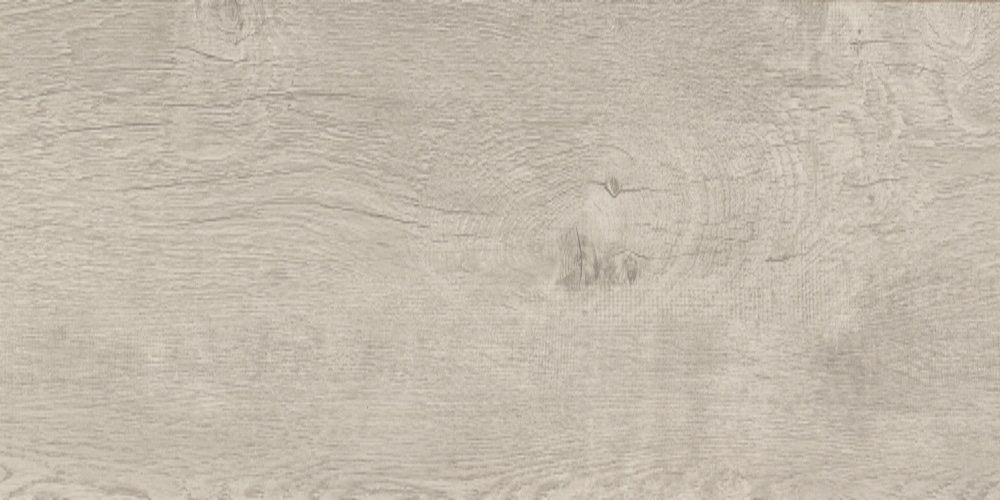

The decorative layer – guarantees highest naturalness

Our decorative laminate is produced by means of classical intaglio print with up to 4 print colours. Substrate material is white or coloured and lightfast special paper soaked in melamine resin and therefore resistant to moisture. An effort, that is well worth it: for an expressive depth effect, maximum brilliance and intense colouration.

High-strength coreboard for maximum structure stability

The HDF coreboard is made of 80% softwood with a high volume weight for a extra structure stability and swell proof to protect it against moisture.

- Overlay, specially impregnated (durable protective layer)

- Decorative laminate, specially impregnated

- aquaResist® special moisture control HDF E1 coreboard

- Balancing laminate

Beautiful from the outside – Quality on the inside

By now, HARO Laminate Floor has been a lasting success story for 25 years. This is not only due to particularly authentic wood reproductions that are almost indistinguishable from the original, but also because of the elaborate technical construction of our laminate floors. Do not expect anything less than Highest Premium Quality for lasting joy with your HARO Laminate Floor.

| Board dimensions | 8 x 193 x 1282 mm (thickness x width x length) |

| Abrasion class | AC4 |

| Silent Pro / Silent CT | 2 mm thick |

| Level of use | 23/32 (For high-traffic residential and commercial applications) |

| Warranty | Up to 25 Years |

| Impact class | IC 2 |

| Scratch resistance | Grade 4 |

| Antistatic class | ASF2 |

Related Articles

Related

Laminate Flooring Top Layer

Specially Impregnated Laminate Top Layer Maximum UV resistance and durability for your laminate floor Brand-name quality means more to us than just producing Premium-Quality Laminate Floors. We take care of everything and always place value on Innovation. We want to...

Laminate Flooring Board Size

Impressive Board Formats Just as every room has its own unique character, every person has individual tastes and needs. So it's great that HARO Laminate Floor offers two different board formats that make every interior design dream come true.The trendy one. The format...